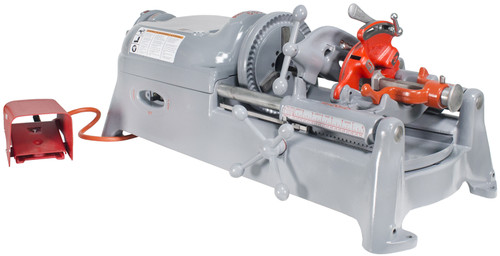

The Steel Dragon Tools® (Reconditioned) RIDGID® 535 Version 1 Pipe Threader has been cleaned, repaired, and prepared for professional use. Each Steel Dragon Tools® (Reconditioned) RIDGID® machine is disassembled, cleaned, inspected, painted, reassembled, and tested. All Steel Dragon Tools® (Reconditioned) RIDGID® machines run like new and feature a one (1) year warranty against manufacturer defects.

Package Includes:

- Steel Dragon Tools® (Reconditioned) RIDGID® 535 V1 Pipe Threader.

- Steel Dragon Tools® (Reconditioned) RIDGID® 341 or 340 Pipe Reamer.

- Steel Dragon Tools® (Reconditioned) RIDGID® 811 Universal Quick-Opening Die Head.

- One (1) set of RIDGID® 47745 1/2 in. to 3/4 in. Universal Alloy Steel Dies.

- One (1) set of RIDGID® 47750 1 in. to 2 in. Universal Alloy Steel Dies.

- Does not include stand.

Specifications:

- Pipe Capacity: 1/8 in. to 2 in. (3 mm to 50 mm).

- Bolt Capacity: 1/4 in. to 2 in. (6 mm to 50 mm).

- Motor: 1/2 HP, single-phase, 115 V, 50/60 Hz, 36 RPM.

- Motor Control: Reverse/Off/Forward controlled by footswitch.

- Spindle Speed: 36 RPM (no load).

- Chuck: Speed Chuck™ with replaceable rocker-action jaw inserts.

- Rear Centering Device: Cam-action, turns with chuck.

- Oiling Pump: Self-priming gerotor.

- Reamer: 1/8 in. to 2 in. (3 mm to 50 mm), RH, five-flute cone.

- Cutter: Self-centering, full floating 820 wheel-type cutter.

- Stand Adapter: Attach old-style 535 machines to a new stand.

- May not be compatible with 815A Die Heads. This machine will come with either a 341 (new style) or 340 (old style) reamer. Machines equipped with the 340 Reamer are not compatible with 815A Die Heads.

To ensure optimal performance and longevity of your pipe threading machine, we recommend greasing and/or lubricating your machine upon arrival and regularly greasing and/or lubricating all moving parts, especially the threading dies and carriage mechanisms. Proper greasing and/or lubrication minimizes wear, reduces friction, and enhances overall machine efficiency. Heavy use of your machine may require more frequent greasing and/or lubrication.

WARNING: This product can expose you to chemicals including Lead, Styrene, Ethylbenzene, and Naphthalene, which are known to the State of California to cause cancer and birth defects or other reproductive harm. Carbon Black, and Glass Wool Fibers which are known to the State of California to cause cancer. For more information, go to www.P65Warnings.ca.gov.

This video goes into great depth of the RIDGID® 300 power drive reconditioning Process, but each of our machines and parts are done with the same care to detail and the end result is a high quality reconditioned tool with warranty.